LED Neon Lights 12V Single Color Custom Flexible Tube Waterproof Features

Our LED Neon Lights are made with a DC12V low-voltage silicone strip, offering a range of benefits. They are odorless, non-yellowing, and waterproof, making them perfect for indoor and outdoor use. The silicone material is corrosion-resistant and weather-resistant, providing superior UV resistance compared to traditional PVC sheaths, ensuring longer-lasting durability and safety. You can use this HW5 Miboxer LED controller to control the lights via the APP or remote.

This cuttable neon light can be trimmed every 2.5cm, giving you the flexibility to create custom designs. For easy installation, purchase extra silicone adhesive, and stick the light bar anywhere you like. With 360-degree bendability, this versatile neon strip is perfect for DIY residential decorations or designing unique business signs.

Product Parameters

Type: Flexible LED Silicone Neon Strips

Size: 6*12mm(W*H)

Length: 5M/Reel,50M/Reel

Cuttable unit: 2.5mm (based on marking interval)

LED Type: 2835 SMD LEDs

LED Quantities: 120LEDs/M

Single Lamp Bead Lumen:20-22(lm)

Working Voltage: DC12V

Power: 6W/M

Emitting Colors: Cool White, Warm White, Red, Blue, Green, Yellow, Pink, Purple, Orange, Ice Blue

Beam Angle: 180°

Waterproof Rating: IP67

CRI: >80Ra

Dimmable: YES

Lifespan: 50,000 Hours

Low Voltage Wiring Method

Method one Soldering Terminal Blocks

1. Use a utility knife to peel off the rubber on the cut surface.

2. Expose the complete welding point guide plate shall prevail.

3. Weld the positive and negative poles of the two

wires with an electric iron (welding wire can be

purchased in the store or prepared by yourself,

recommended 0.75 square meters of wire)

4. Sets of protective plug waterproof glue to connect the

transformer (protective plugs can be purchased in the

store, if not, you can directly hit the waterproof glue)

Method two non-welding connector

1. Prepare to cut a good need to wire the low-voltage

flexible light tape

2. Open the buckle cover of the non-soldering wire head

(non-soldering wire head can be purchased in the store)

3. Light strip into the non-welded wire head interface and

press (note that the tip of the wire head between the two

need to be pierced into the strip’s guide plate)

4. Buckle the connector buckle cover can be connected

to the transformer (connecting line uniform positive and

negative poles to distinguish between the transformer does

not light up positive and negative poles to adjust the next)

Low Voltage Transformer Connection

Special reminder: 12V/24V low-voltage lamps must be used through the corresponding transformer wiring; it is strictly prohibited to plug them directly into the 110V or 220V power line.The store cannot be dealt with after-sales if connected to the 110V or 220V power supply, caused by the burnt lamp, scrapped.

Special explanation

The strip is 12V with the use of a 12V transformer

Lighting is 24V with the use of a 24V transformer

When connecting the transformer, please note that you need to distinguish between positive and negative poles.

The total power of the strip must not exceed the rated power of the transformer.

The length of each 12V strip in series shall not exceed 5 meters, and the length of each 24V strip in series shall not exceed 10 meters.

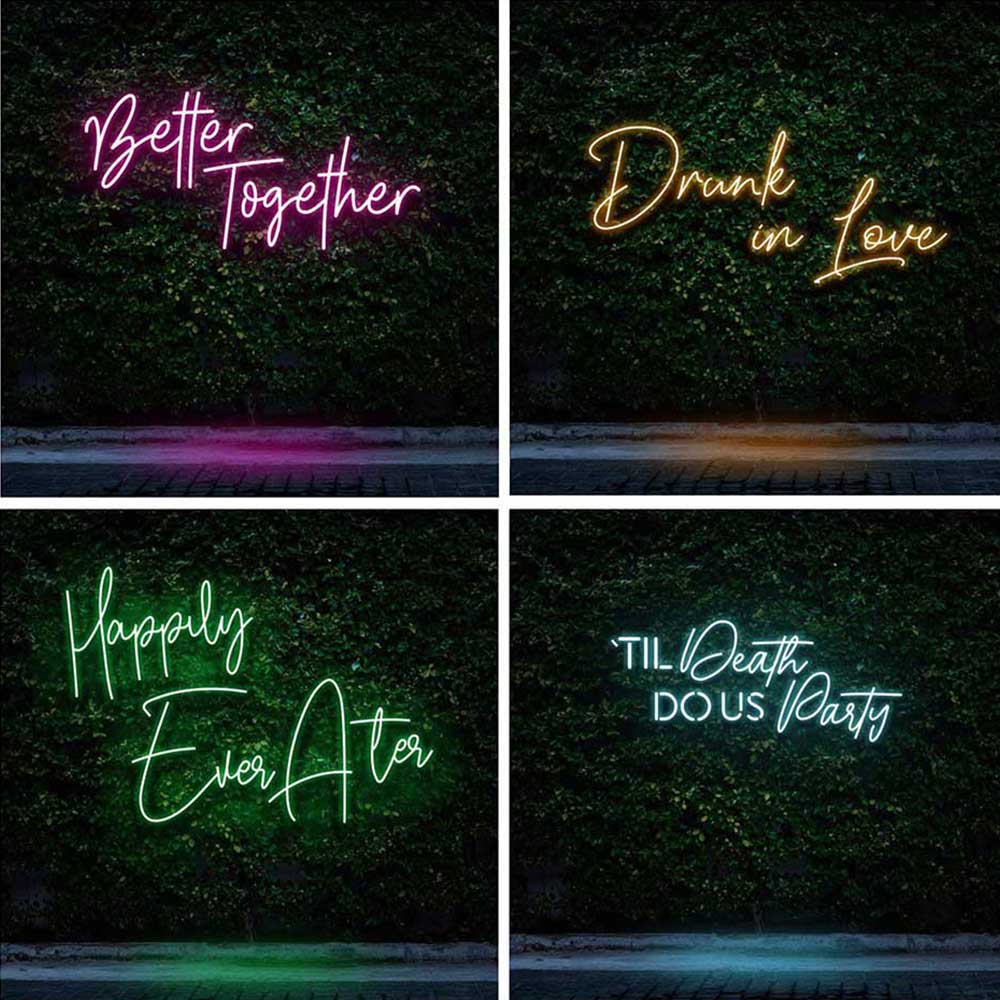

Neon scene application effect diagram

Reviews

There are no reviews yet.